Our repair division, formerly known as Synergy Pipe Services, has full repair capabilities for Line Pipe and Oil Country Tubular Goods (OCTG). Our services are fully portable, whether your pipe is located at the port, laydown yard, coating facility, or right-of-way, we can dispatch crews swiftly and in some cases within the same day to repair your damaged inventory. One of the main aspects setting us apart from our competitors is the fact we offer Technical Inspection & Testing Services. This means our personnel understand industry Specifications, Codes, and Recommended Practices. And foremost, all our work is checked before it is released to our clients as part of our standard operating procedures (SOP).

Our pipe repair clients range from Pipe Mills, Trading Companies, Master Distributors, EPC Companies, Pipeline and Utility Operators.

Here is a list of our core pipe repair services:

Line Pipe

- Torch Cutting and Beveling (from 1 inch OD and up)

- Plasma Cutting and Beveling (Stainless Steel and Other Alloys Up to 60 inch OD)

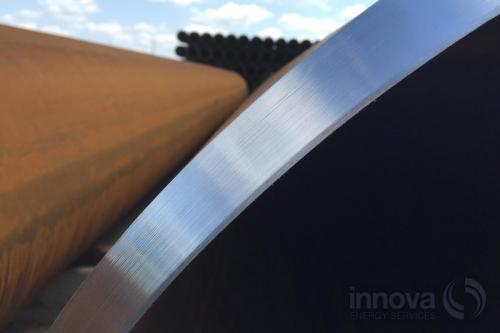

- Machine Beveling (Up to 60 inch OD)

- Cold Cutting and Beveling (Up to 60 inch OD) (Download Brochure)

- Counterboring

- Flange Refacing

- Milling

- Hydraulic Expansion (AKA De-Denting, Up to 60 inch OD)

- Re-Rounding Out-of-Round Pipe (Up to 60 inch OD)

- Pipe Straightening (portable up to 14 inch OD)

- Abrasive Blasting (OD and ID)

- Blast-Roll & Spray (BRS)

- Remediation of Seawater Contamination

- Removal of Coatings

- Removal of Surface Imperfections and Defects (OD and ID)

- Remediation of High Residual Magnetism

- Repair of Coatings (FBE, ARO, 3LPP, and others)

- Application of Whitewash Paint

- Application of Stencils and Markings

- Bundling for Domestic or International Transport

- Inventory Management Solutions (e.g. Application of RFIDs, Barcodes, Special Markings, etc.)

OCTG

- Clean and Re-Dope Connections

- Visual Thread Inspection (VTI)

- Special End Area Inspection (SEA)

- Portable Electromagnetic Inspection (EMI)

- Prove-Ups (UT/MT and PT)

- No-Drift Repair

- ID Honing

- Removal of Dents

- Hydrostatic Testing

- Pipe Straightening (Portable up to 13-3/8 inch casing)

- Removal of ID Reflectors

- Blast-Roll & Spray (BRS)

- Application of Stencils and Markings

- Bundling for Domestic or International Transport

Operator Qualifications Verified Through:

Proud Members of:

Innova is a certified minority-owned business by the state of Texas.

“Innova Energy Services is our only call when we need pipe repaired or inspection services. The customer service is impeccable. Hernan has flown on two hours’ notice to rural Colorado to inspect pipe at the right of way for us. We have had crews mobilized on holiday weekends for emergency work. They go above and beyond each and every time to help us and our customers. We look at Innova as a vital extension of our company.”

Kurt Swendson

Salzgitter Mannesmann International (USA) Inc.

General Manager Line Pipe